6. Group assignment: Analysis of flow past backward

facing step by using realizable k-epsilon turbulence model

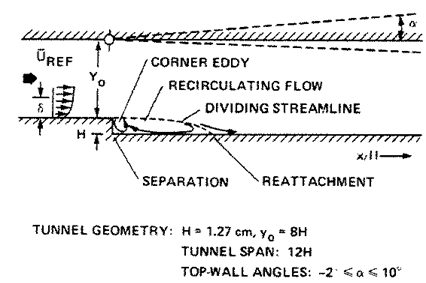

The project is aimed at the

investigation of flow pattern past a backward facing step of variable (a) top wall angle. Results are to be compared with

experimental data.

Figure 1. Geometrical model and flow structures.

The backward facing step is located at

the lower wall of a channel. The channel has an even width in the direction

perpendicular to the x-y plane, that is, a two-dimensional flow can be assumed.

The channel height is Y0(=8H) on the upstream side and Y0+H on the downstream side

of the step; the step height is H.

Since each dimension can be expressed in terms of H, only H=12.7mm is specified. The origin of the coordinate system (x=0,

y=0) is specified by the upper corner of the step, the inlet is located at x=-2H. The outlet cross-section is at 15H away from the step. The upper wall

can be tilted about a turning point just above the step. In this way, the

channel can shrink or expand in steamwise direction

creating a positive or negative pressure gradient. Angle a is measured between the upper (tilted) wall and the

initial flow direction.

Boundary

conditions

Velocity and turbulence characteristics

are imposed at the inlet boundary according to bfs_belepes.prof. It is important to note, that inlet

quantities are specified at x=-2H (upstream from the step), therefore the

geometrical model need to be prepared correspondingly. Turbulent kinetic energy

(k), turbulent dissipation rate (epsilon) and specific dissipation rate (omega)

are contained by the profile file. Use pressure boundary condition at the

outlet, and no-slip condition on solid walls.

The reference velocity used in the

evaluation of dimensionless quantities is Uref=44.2m/s .

Note that, this is not a boundary condition!

Task 1. (3 points)

Preparation of the geometrical model with alfa=-2°,

0°, 6° and 10°;

Generation of block structured mesh;

Please mind that:

- the boundary layers on

solid walls, require a proper wall-normal resolution;

- and the shear layer,

separated from the upper edge of the step, also needs refinements.

Task 2. (3 points)

Selection and parameterization of boundary condition in

FLUENT;

Use the given inlet profile for specifying inlet

boundary conditions!

Task 3. (3 points)

Check your mesh for meeting turbulence model criteria

as well as resolution required at highly sheared zones for alfa=0 lid angle:

- check if the value of y+ is within the range

required by the turbulence model; if not, modify your mesh accordingly;

- perform adaptive refinement in the vicinity of the

shear layer and evaluate changes in flow characteristics.

Task 4. (3 points)

Run simulations with realizable k-epsilon turbulence

model for 4 different alfa angle!

- Plot velocity profiles downstream from the step in

1H, 2H, 3H and 4H distances!

- Compare the calculated reattachment lengths resulted

with measured values (xR/H)!

- Compare the calculated pressure coefficient (cp) profiles, with special attention to the

correct selection of reference values.

Measured data:

Position of the reattachment point

|

Lid angle |

Reattachment length |

Error |

|

a [°] |

Xr/H |

dXr/H |

|

-2 |

5.82 |

-0.08 |

|

0 |

6.26 |

-0.1 |

|

6 |

8.3 |

-0.15 |

|

10 |

10.18 |

-0.5 |

Pressure coefficient (cp)

on lower wall (on the side of the step)

|

X/H |

a=-2 |

a=0 |

a=6 |

a=10 |

|

-8.5 |

0 |

0.0039 |

0.0117 |

0.0088 |

|

-6.5 |

0 |

0 |

0.0136 |

0.0108 |

|

-4.5 |

-0.0059 |

-0.0048 |

0.0166 |

0.0187 |

|

-2.5 |

-0.0296 |

-0.0231 |

0.0214 |

0.0266 |

|

-0.5 |

-0.0642 |

-0.0472 |

0.0283 |

0.0512 |

|

0 |

-0.0859 |

-0.0607 |

0.0361 |

0.061 |

|

0.5 |

-0.0899 |

-0.0636 |

0.0331 |

0.06 |

|

1 |

-0.0899 |

-0.0665 |

0.0312 |

0.0571 |

|

1.5 |

|

|

0.0292 |

0.0571 |

|

2 |

-0.1017 |

-0.0742 |

0.0253 |

0.0571 |

|

2.5 |

|

|

|

0.0502 |

|

3 |

-0.1037 |

-0.0762 |

0.0185 |

0.0482 |

|

3.5 |

-0.083 |

-0.0665 |

0.0253 |

|

|

4 |

-0.0464 |

-0.0424 |

0.04 |

0.0581 |

|

4.5 |

0.0049 |

0.0077 |

0.0585 |

|

|

5 |

0.0494 |

0.0482 |

0.0829 |

0.0876 |

|

5.5 |

0.0771 |

0.0782 |

|

|

|

6 |

0.1037 |

0.1129 |

0.1297 |

0.1251 |

|

6.5 |

0.1205 |

0.1303 |

|

|

|

7 |

0.1275 |

0.1389 |

0.1667 |

0.1556 |

|

8 |

0.1304 |

0.1515 |

0.1989 |

0.1871 |

|

8.5 |

|

|

0.2115 |

|

|

9 |

0.1225 |

0.1535 |

0.2203 |

0.2117 |

|

9.5 |

|

|

0.231 |

|

|

11 |

0.0978 |

0.1477 |

0.2544 |

0.2551 |

|

12 |

|

|

0.2641 |

|

|

13 |

0.0751 |

0.1409 |

0.2749 |

0.2846 |

|

15 |

0.0534 |

0.1342 |

0.2924 |

0.3073 |

|

17 |

0.0385 |

0.1303 |

0.308 |

0.328 |

|

19.5 |

0.0168 |

0.1285 |

0.3265 |

0.3448 |

|

21.5 |

0.001 |

0.1246 |

0.3402 |

0.3596 |

|

23.5 |

-0.0168 |

0.1227 |

0.3528 |

0.3723 |

|

25.5 |

-0.0346 |

0.1227 |

0.3674 |

0.3813 |

|

27.5 |

-0.0494 |

0.1218 |

0.3821 |

0.3921 |

|

29.5 |

-0.0652 |

0.1218 |

0.3889 |

0.4011 |

|

31.5 |

-0.085 |

0.1199 |

0.4035 |

0.409 |

|

33.5 |

-0.1048 |

0.116 |

0.4133 |

0.4139 |

|

35.5 |

-0.1236 |

0.1189 |

0.4279 |

0.4198 |

|

37.5 |

-0.1463 |

0.1141 |

0.4347 |

0.4209 |

Pressure coefficient (cp)

on upper wall (opposite to the step)

|

X/H |

a=-2 |

a=0 |

a=6 |

a=10 |

|

-5 |

0.0178 |

0.0087 |

0.0039 |

-0.0108 |

|

3 |

0.0306 |

0.0414 |

0.0799 |

0.0896 |

|

5 |

0.03 |

0.0511 |

0.1248 |

0.1536 |

|

7 |

0.0296 |

0.0598 |

0.1627 |

0.1989 |

|

9 |

0.0425 |

0.081 |

0.1989 |

0.2471 |

|

11 |

0.0504 |

0.0993 |

0.232 |

0.2816 |

|

13 |

0.0454 |

0.1118 |

0.2612 |

0.3092 |

|

15 |

0.0336 |

0.1138 |

0.2846 |

0.3338 |

|

17 |

0.0286 |

0.1206 |

0.308 |

0.3545 |

|

19 |

0.0148 |

0.1216 |

0.3246 |

0.3683 |

|

21 |

0.001 |

0.1216 |

0.3402 |

0.3821 |

|

23 |

-0.0158 |

0.1207 |

0.3538 |

0.389 |

|

25 |

-0.0296 |

0.1236 |

0.3713 |

0.3979 |

|

27 |

-0.0474 |

0.1217 |

0.384 |

0.4029 |

|

29 |

-0.0642 |

0.1208 |

0.3947 |

0.4079 |

|

31 |

-0.0811 |

0.1189 |

0.4055 |

0.4178 |

|

33 |

-0.1038 |

0.116 |

0.4133 |

0.4178 |

|

35 |

-0.1236 |

0.1179 |

0.4298 |

0.4228 |

|

37 |

-0.1464 |

0.1131 |

0.4396 |

0.4239 |

Task 5. (3 points)

Plot the streamlines colored by velocity magnitude,

the static and total pressures as well as the turbulent kinetic energy and save

images in TIF format.

Briefly describe the investigation aims, the solution

methods, and the results in comparison to measurement data.

Prepare your report in PowerPoint (.PPT) format and

upload to the folder specified by the practice leader!